7005 Aluminum Fabrication Guidelines

WELDING

The suggested TIG filler rod is ER5356, containing magnesium that provides good strength and ductility to the weld metal.

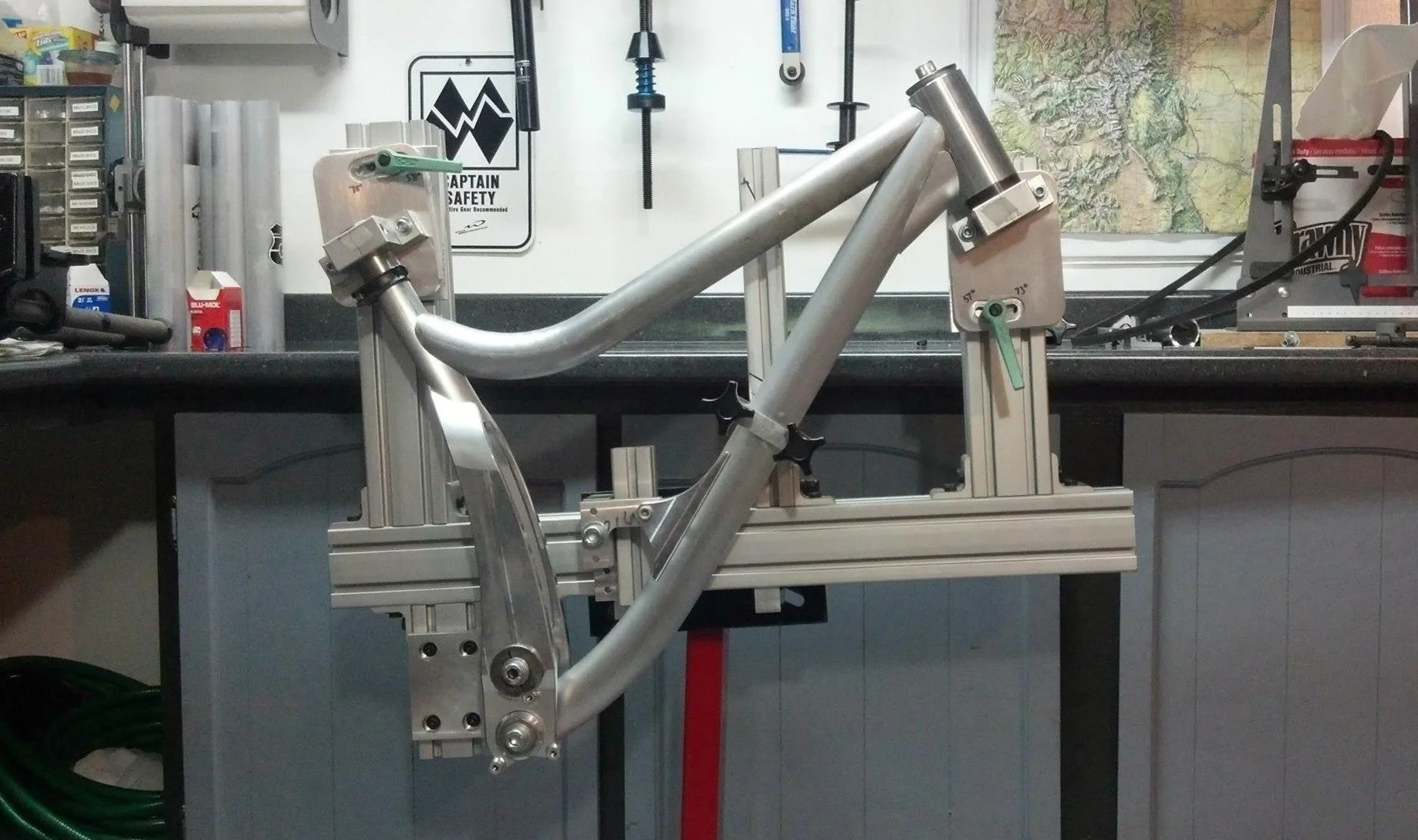

ALIGNING

Alignment after welding should be done within 6 hours, while the material around the weld is still soft. Because 7005 alloy hardens quickly with age, delaying alignment requires greater force, which increases the risk of hidden damage to the tubes or welds and can shorten the frame’s lifespan. For staged builds, each subassembly should also be aligned within the same 6-hour window.

ARTIFICIAL AGE

For 7005-T6 condition: age for 6 hours at 200°F (±10°F), followed by 4 hours at 320°F (±10°F)

After cooling to room temperature, the frame or parts can be handled, machined, or assembled without further thermal treatment. Note: Standard processing of 7005 frames does not require solution heattreatment and quench after welding.

Gilmour Bicycles